Four-sided grinding machine SHP-8/200

₴290 000return of goods within 14 days by agreement

Showing all 11 results

– Excellent price;

– 2 brushes are located on both sides of the machine. After processing on a metal brush, the workpiece is fed to an abrasive brush;

– Inverter for brush rotation – the machine can be used as a grinder (mod.SD-1i);

– Czech components (brushes);

ADVANTAGES:

– 2 brushes are located on both sides of the machine. After processing on the metal brush, the workpiece is fed to the abralon brush;

– Automatic part feed (German conveyor belt);

– Italian gearbox from STM;

– Smooth adjustment of the workpiece feed speed from 2 to 12 m/s;

– Inverter for brush rotation – the machine can be used as a grinder (mod.SD-1Ti);

– Czech components (brushes);

– Separate reverse of each working brush

ADVANTAGES:

– Simultaneous processing of the part with two brushes (metal and abrolone);

– Italian gearbox from STM;

– Automatic part feed (German conveyor belt);

– Inverter for brush rotation – the machine can be used as a grinder (mod.SD-2i);

– Smooth adjustment of the workpiece feed speed from 2 to 12 m/s;

– Separate motor for each unit;

– Czech components (brushes);

– Separate reverse of each working brush;

Grinding machine SHD-3-1000U The SHD-3-1000 sanding machine is designed for sanding parts of woodworking and furniture production with complex profile shapes, including furniture facades. The special machine SHD-3-1000 (hereinafter referred to as the machine) is used for profile grinding of molded and furniture parts at woodworking enterprises, including furniture facades and carved parts after processing…

It is intended for grinding of woodworking production linear parts of complex profile shape as well as flow grinding of furniture production blanks.

Standard delivery set includes

It is designed for grinding of woodworking production linear parts of complex profile shape as well as flow grinding of furniture production blanks. The standard delivery set includes 4 grinding heads: 2 upper (h=200 mm) with counter-rotating spindles and 2 side heads (h=100 mm) and a roller automatic conveyor with smoothly variable feed speed.

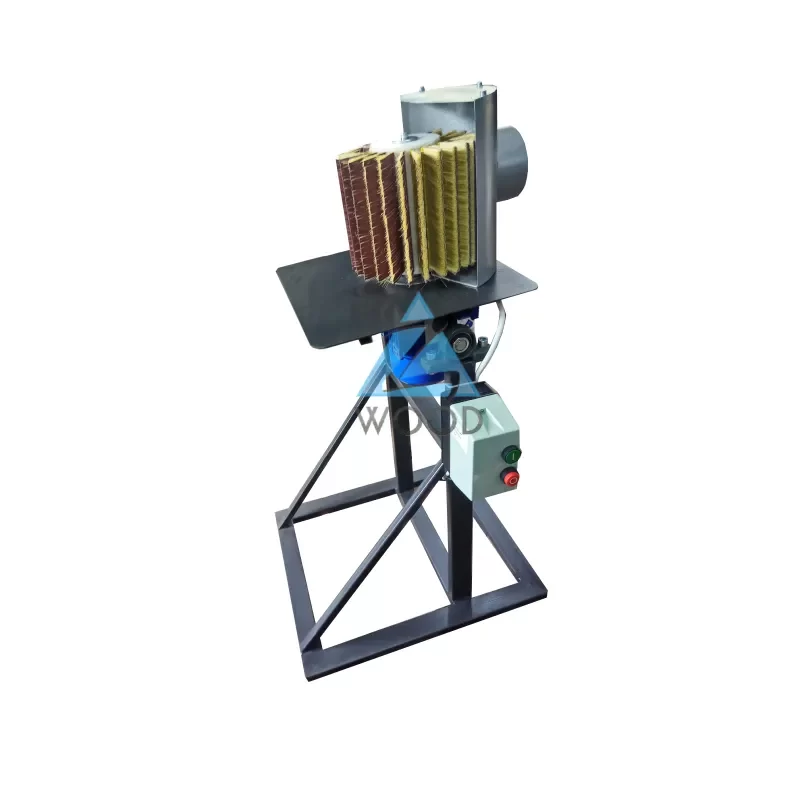

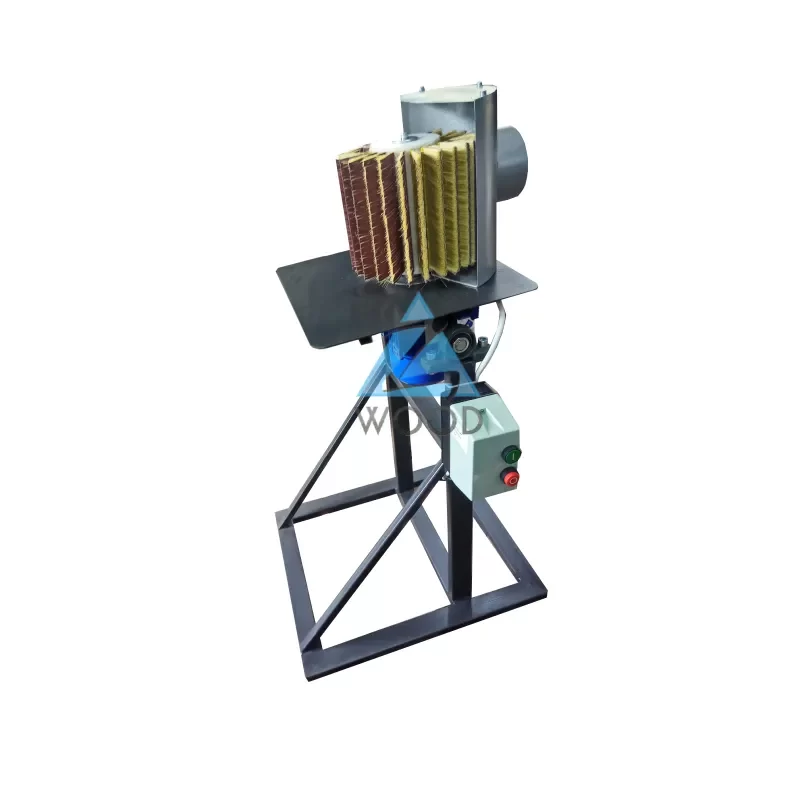

The brush sweeping system we offer is an effective means of increasing labor productivity and reducing production costs.