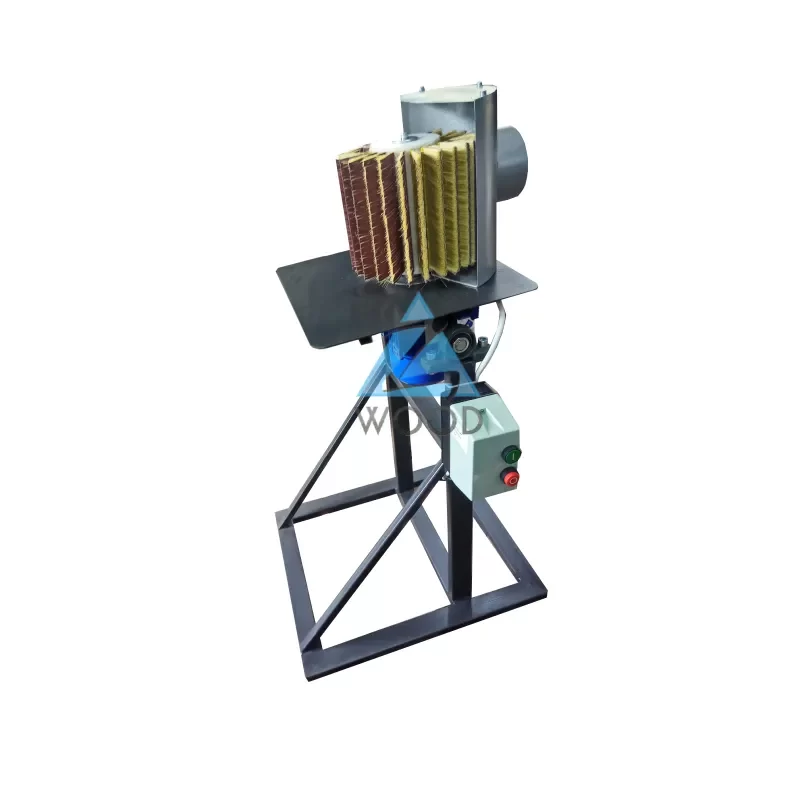

Grinding machine SH-2

₴99 620

ADVANTAGES:

– Simultaneous processing of the part with two brushes (metal and abrolone);

– Italian gearbox from STM;

– Automatic part feed (German conveyor belt);

– Inverter for brush rotation – the machine can be used as a grinder (mod.SD-2i);

– Smooth adjustment of the workpiece feed speed from 2 to 12 m/s;

– Separate motor for each unit;

– Czech components (brushes);

– Separate reverse of each working brush;

Delivery methods

- We ship by any transport company or pick up yourself

Description

Grinding machine SH-2

SH-2 is a high-quality sanding machine designed for finishing wood and other materials such as MDF, plywood and plastics. The machine ensures perfect surface smoothness, making it ready for further finishing, painting or varnishing. It is used in various woodworking industries such as furniture production, finishing works and production of decorative elements.

Main advantages of SH-2:

- High precision processing:

Grinds workpieces with minimal deviations, providing a flat and smooth surface. - Versatility of application:

Suitable for working with various types of materials including wood, MDF, plywood, plastic and composite materials. - Speed control:

Adjustable material feed speed allows the machine to be adapted to different types of processing. - Low power consumption:

Energy-efficient operation with optimised energy costs. - Ease of maintenance:

Easy to maintain and replace consumables, reducing downtime and improving productivity.

Technical specifications:

- Working width of the workpiece: up to 500 mm.

- Maximum workpiece height: up to 100 mm.

- Engine power: 4 kW.

- Feed speed: adjustable, from 5 to 15 m/min.

- Type of abrasive material: fabric and paper sanding belts, special discs.

- Dust removal system: built-in system for removing dust and chips.

Application areas:

- Furniture production: finishing of facades, tabletops and other furniture elements.

- Decorative items: processing of parts before painting or varnishing.

- Building materials: sanding of wooden and plastic elements.

- Craft work: creating smooth and even surfaces for artistic products.

Design features:

- Dust removal system: reduces contamination of the workspace and improves work safety.

- Adjusting the sanding belt: easily adjustable belt to achieve the desired roughness.

- Robust construction: high stability and minimal vibration during operation.

SH-2 is a reliable and efficient solution for finishing materials with maximum processing quality, ensuring durability and precision of work.

PURPOSE:

Designed for profile grinding of wooden blanks of any size.

SCOPE OF APPLICATION:

Enterprises and workshops for the production of furniture, joinery and other woodworking industries.

ADVANTAGES:

– Simultaneous processing of a part with two brushes (metal and abrillon);

– Italian gearbox from STM;

– Automatic part feed (German conveyor belt);

– Inverter for brush rotation – the machine can be used as a grinder (mod.SD-2i);

– Smooth adjustment of the workpiece feed speed from 2 to 12 m/s;

– Separate motor for each unit;

– Czech components (brushes);

– Separate reverse of each working brush;

General and technical characteristics:

| El. Engine | 2 pcs x 1.5 kW/950 rpm. |

| Supply voltage | 3 фаз./380В/50Hz |

| Number of shafts | 2х200 mm |

| External Ø instr. | 150-250 mm |

| Max. Width of Workpiece | 200 mm |

| Total weight | 250 kg |

| Frequency converter * (optional mod.SD-2i) | 300-1500 rpm*2 pcs |

| Dimensions L/W/H | mm |

The warranty period for the supplied products is 1 year

Characteristics

| Country of origin | Ukraine |

| ЧПУ | No |

| Grinding width | 200 mm |

| Suction pipe diameter | 125 mm |

| Maximum feed rate | 12 m/min |

| Feeding the workpiece | Automatic |

| Feed motor power | 1.5 kW |

Reviews

There are no reviews yet.