Grinding machine SHD-3-1000U

Delivery methods

- We ship by any transport company or pick up yourself

Description

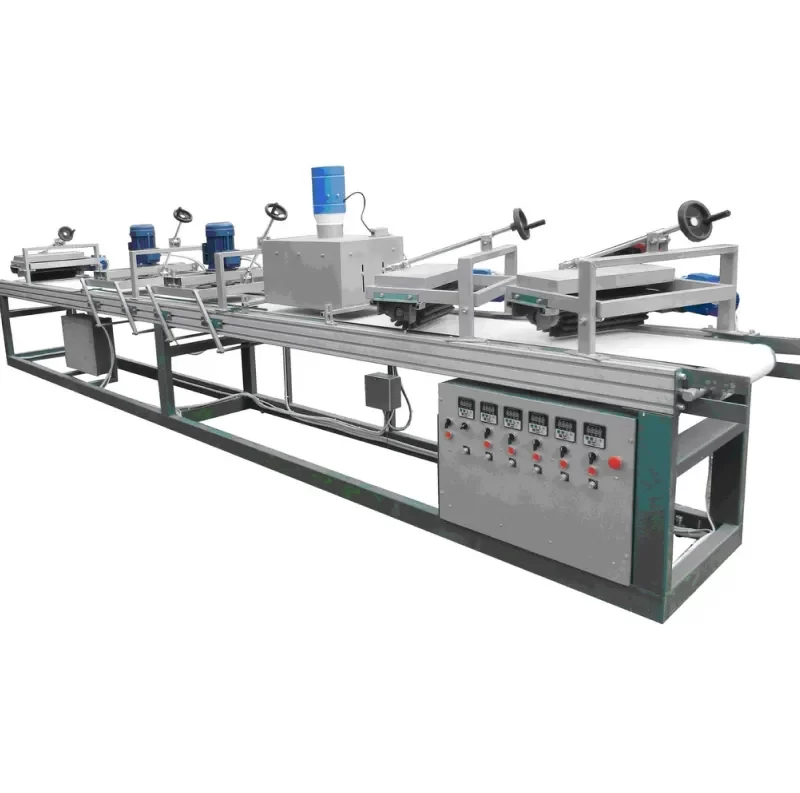

Grinding machine SHD-3-1000U

The SHD-3-1000 sanding machine is designed for sanding parts of woodworking and furniture production with complex profile shapes, including furniture facades.

The special machine SHD-3-1000 (hereinafter referred to as the machine) is used for profile grinding of molded and furniture parts at woodworking enterprises, including furniture facades and carved parts after processing on CNC machines.

Purpose of the main components:

– 1 performs grinding along the axis of movement of the workpiece.

– Unit 2 performs grinding perpendicular to the axis of movement of the workpiece (two rows of grinding drums of 5 pcs., 100 mm wide each).

– Unit 3 performs grinding in the opposite direction from the axis of movement of the workpiece.

All units are equipped with oscillation, which significantly improves the quality and uniformity of grinding.

For grinding carved parts after processing on CNC machines, it is possible to install or replace one of the units with a disk (plate) unit consisting of two rows of grinding discs (5 pcs., diameter 200 mm).

The intensity of workpiece processing is regulated using inverters from the control panel: the speed of rotation of the working tools and the speed of workpiece feed change. The machine is made to order with the possibility of changing the number and order of units, as well as technical characteristics depending on the customer’s requirements.

**Technical specifications:**

– Material of blanks: solid wood, plywood, veneered panels.

– Width of blanks: 1000 mm.

– Feed of blanks: automatic, adjustable.

– Installed power:

– Conveyor motor: 0.37 kW;

– Working motors: 4×3.0 kW.

– Power supply: 4×380 V, 50 Hz.

– Machine dimensions:

– Height: 1350 mm;

– Width: 1150 mm;

– Length: 2200 mm.

– Weight: 320 kg.

– Width of conveyor belt: 1000 mm.

– Length of conveyor belt: 3400 mm.

– Belt feed speed: 2-12 m/min (electronic adjustment).

The machine manufacturer provides the ability to make changes to the technical specifications and functionality of the equipment in accordance with the customer’s requirements. The production period is 65 working days.

Reviews

There are no reviews yet.