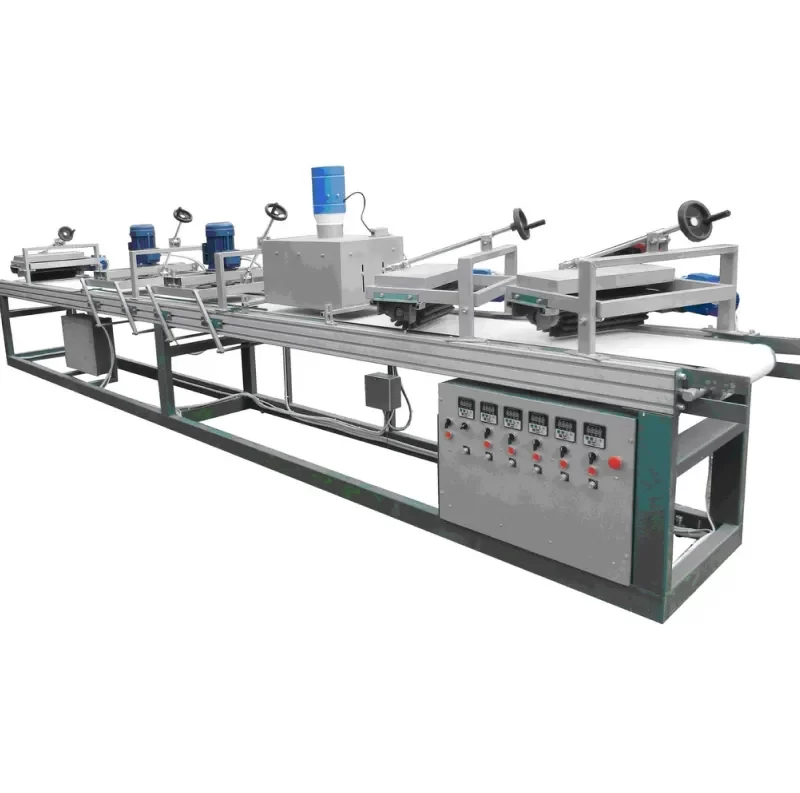

Length Counter SD-12

₴5 400

The counters are designed to measure the length of various long flat products, such as film, conveyor belt, paper, etc.

The measurement error is no more than ±0.1%, adjustable by the manufacturer ±0.01%.

Delivery methods

- We ship by any transport company or pick up yourself

Description

Length counter SD-12

The SD-12 length counter is a high-precision equipment designed to measure the length of various materials such as fabric, film, tape, cable, wire, paper and other long products. The machine is widely used in manufacturing and processing industries to automate the process of measuring and accounting for the length of products.

Main characteristics of the SD-12 length counter:

- Operating principle: The SD-12 length counter uses sensors or roller mechanisms that detect the movement of material and count its length as it passes through the system. This ensures accurate measurement even in large volumes of work.

- High accuracy: Measurement accuracy can reach several millimeters depending on the type of material.

- Operating speed: The SD-12 length counter supports various operating speeds, allowing it to be adapted to the specifics of production. It operates efficiently at high speeds, ensuring continuous material processing without loss of accuracy.

- Automatic Stop: The machine is equipped with an automatic stop function that is activated when the set length of material is reached. This prevents overruns and helps maintain accurate accounting.

Advantages of the SD-12 length counter:

- Accurate and fast work:

The counter provides accurate measurements and can handle materials at high speeds, improving overall productivity. - Process automation:

The automatic stop system and the ability to integrate with accounting systems minimize the human factor and speed up production processes. - Versatility:

The SD-12 length counter is suitable for a wide range of materials, making it ideal for a variety of industries including textile, packaging and cable. - Ease of operation:

The device has a simple interface and control panel, which makes it convenient for operators to operate. - Reduction of material loss:

Accurate measurement and automatic stop prevent material waste and minimize waste, thus saving resources. - Durability and reliability:

The machine is made of durable materials, which increases its service life and reduces maintenance costs.

Application of the SD-12 length counter:

- Production lines:

Used in production lines to measure and record the length of materials such as textiles, film, cable, wire and other long products. - Warehouse operations:

In warehouses, the SD-12 length counter helps accurately measure the length of materials when they are stacked or moved, facilitating inventory control and improving accounting. - Paper and packaging production:

The counter is actively used in production processes related to the production of paper rolls, packaging film and other materials. - Production of cables and wires:

In cable and wire production, the SD-12 length counter allows for accurate measurement of the length of cables and wires, which is important for maintaining quality standards.

The counter software allows the following functions to be performed:

- Correction depending on the diameter of the counting roller.

- Correction based on the results of test measurements.

- Programming the counter for 10 lengths, each of which can be changed.

- The counter roller is held in the non-working position by a lock.

The meter is powered from the mains via a 12 V adapter, which eliminates electric shock and does not require grounding. It is possible to order from 24 volts or from another voltage source.

TECHNICAL SPECIFICATIONS

Measurement accuracy, %±0.1

Power supply, V220

Weight, kg 3.5

Characteristics

| Main | |

|---|---|

| State | Used |

Reviews

There are no reviews yet.