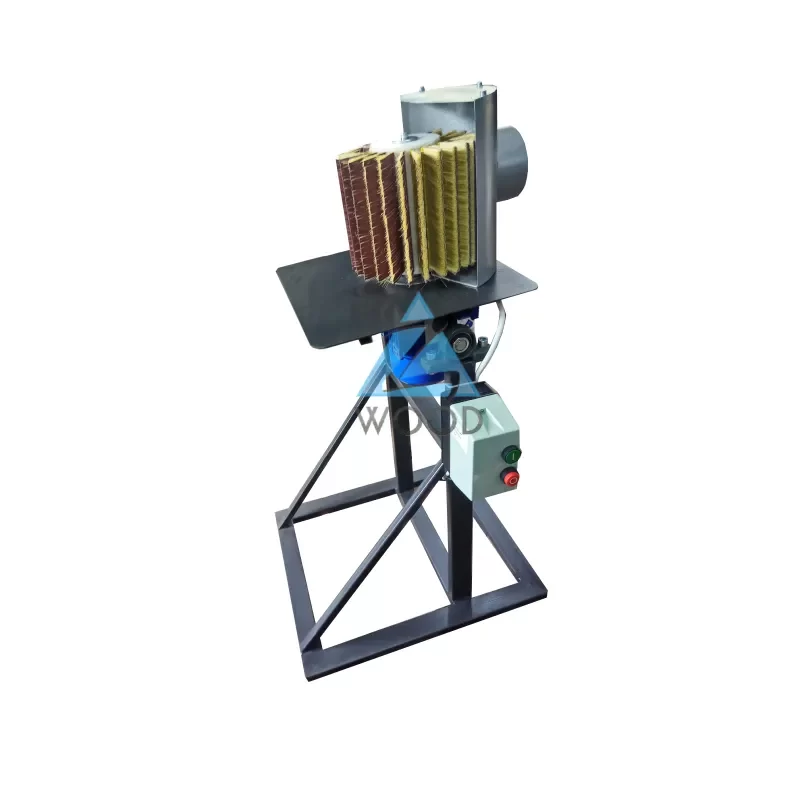

Machine for rubbing in low wax RSP-4/400

₴310 000

It is intended for rubbing oil wax into wooden blanks with a maximum thickness of up to 60 mm. It is used in board finishing lines, including after SD-type aging machines.

Delivery methods

- We ship by any transport company or pick up yourself

Description

Machine for rubbing in low wax RSP-4/400

Oil wax rubbing machine RSP-4/400 is designed for uniform and effective application of oil wax on wooden and other porous surfaces. This machine is widely used in the furniture and woodworking industries, as well as in the production of building materials, where high-quality surface treatment is required to protect and improve the appearance.

Main characteristics of the RSP-4/400 oil wax rubbing machine:

- Operating principle: The machine operates on the basis of a rotating drum or roller, which evenly distributes the oil wax over the surface being treated. The device is equipped with a wax feed control system, which allows for precise dosing of the amount of material for rubbing in and prevents its excessive consumption.

- Processing width: The machine is designed to process materials up to 400 mm wide, which allows you to work with various sizes of wooden panels, tabletops, doors and other products. All parameters, including speed and wax feed, are adjusted via the control panel, which simplifies operation.

- Energy Saving: The machine uses energy efficient components, which reduces energy consumption and reduces operating costs. This makes it more profitable in the long run.

- Construction: The machine has a strong and stable construction made of high-quality materials, which will ensure its durability and reliability during intensive use. It is also equipped with overload and emergency protection mechanisms.

- Suitable for various materials: The RSP-4/400 oil wax rubbing machine can work with various types of wood, as well as other materials that require protective coatings, such as MDF, plywood and plastic.

Application of the RSP-4/400 oil wax rubbing machine:

- Furniture production:

The machine is used to treat wooden products such as tabletops, cabinets, doors and other furniture components. Rubbing in oil wax gives the surface a beautiful, durable and water-repellent layer. - Construction:

In the construction industry, the machine is used to apply wax to wooden elements used in interior decoration, as well as to panels and other surfaces that require protection. - Woodworking:

The machine is used to process wooden products, which improves their appearance and ensures durability. Wax applied to the surface improves texture and protects against moisture and dirt. - Production of wooden floors and coverings:

For wood floors and coverings, the use of the machine allows you to achieve a high-quality and uniform coating, ensuring durability and resistance of the surface.

5 reasons to buy RSP-4

Full cycle of rubbing and polishing the workpiece in one pass

Smooth speed control of each unit individually

Digital indication of the rotation frequency of each unit

Easy-to-remove tool for each unit for washing

Conveyor belt made in Germany, resistant to various “aggressive” substances and UV radiation

PURPOSE:

It is designed for rubbing oil wax into wooden blanks with a maximum thickness of up to 60 mm. It is used in board finishing lines, including after SD-type aging machines.Functionally, it consists of a base with a conveyor feed of the blank, 2 height-adjustable units with disk brushes or PADs and 2 units with cylindrical brushes (at the input and output of the machine).

The feed speed of the blank is smoothly adjusted using a frequency controller (2-15 m/min). The rotation speed of the working tool is also adjusted by frequency converters.The machine is equipped with an ultraviolet drying unit with a power of 3 kW.

Reviews

There are no reviews yet.