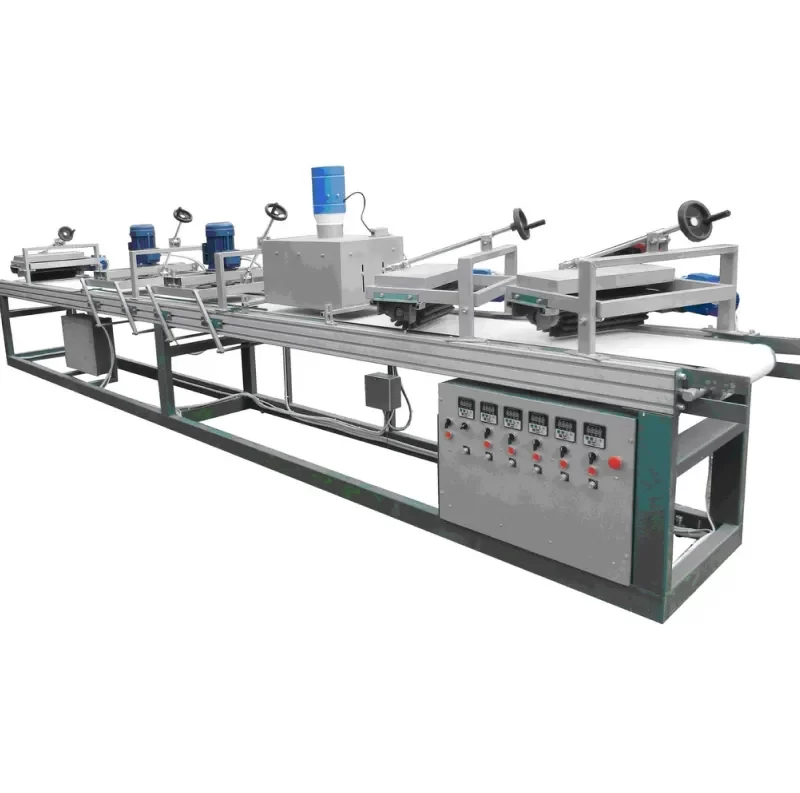

Machine for rubbing oil wax RS-3

₴128 430

It is intended for rubbing oil wax into wooden blanks with a maximum thickness of up to 60 mm. It is used in board finishing lines, including after aging machines of the SSD type. Functionally, it consists of a base with a conveyor feed of the blank, 3 height-adjustable units with cylindrical brushes. The 1st and 2nd brushes are located at an angle of 200

Delivery methods

- We ship by any transport company or pick up yourself

Description

Machine for rubbing oil wax RS-3

The RS-3 oil wax rubbing machine is designed to effectively apply and rub oil wax onto wooden surfaces. This machine is used in the furniture and woodworking industry to process various products such as furniture, wood panels, floors and other wood products. Rubbing oil wax improves the appearance of wood, giving it a beautiful texture and protective properties.

Main characteristics of the RS-3 machine:

- Workflow: The machine is equipped with a system that allows for the oil wax to be applied evenly to the wood surface and rubbed into the pores of the wood. This helps to penetrate deeply into the structure of the material, providing long-lasting protection and improving its appearance.

- Processing types: The oil wax rubbing machine can work with different types of wood and different types of oil wax, including solid and liquid compositions.

- Adjustment of parameters: The RS-3 machine allows you to adjust the feed rate of the material, the amount of the applied composition and the pressure on the surface, which makes it possible to achieve the desired result depending on the type of wood and the composition of the oil wax.

- Versatility of application: Can be used for processing both small and large items, such as tabletops, furniture fronts, door and window frames.

- Design and safety: The machine is equipped with overload and overheat protection system, which improves operating safety and extends the service life of the equipment.

- Efficiency in operation: The machine is characterized by high productivity and quality of processing, allowing large volumes of products to be processed in a short time, while maintaining high quality of processing and application of the protective layer.

Advantages of using the RS-3 machine:

- Even application:

The machine ensures uniform and precise rubbing of oil wax, which is impossible to achieve manually. This is especially important when processing complex and large surfaces. - Improving the appearance of wood:

Rubbing in oil wax allows you to highlight the natural texture and pattern of the wood, giving it depth and richness of color. - Wood protection:

Oil wax not only improves the appearance of wood, but also creates a protective layer that prevents moisture, dirt and damage from penetrating, keeping the wood in good condition for a long time. - Time saving:

Using the RS-3 machine significantly speeds up the processing process compared to manual work, which increases productivity and reduces labor costs. - Ease of use:

The machine is equipped with an intuitive control system and easily adjustable parameters, which simplifies setup and allows the operator to easily adapt to different types of work.

Application of the wax oil rubbing machine:

- Furniture processing:

It is used to treat furniture fronts, tabletops, doors and other wooden elements, giving them a deeper color and protection from external influences. - Woodworking for interior:

It is used for treating panels, floors and other wooden surfaces in the interior, providing long-lasting protection and improving aesthetic qualities. - Production of wooden products:

Effective in the production of wooden parts for various purposes such as window frames, doors, furniture and decorative elements.

Conclusion:

The RS-3 oil wax rubbing machine is an important piece of equipment in the woodworking industry. It provides high-quality and fast application of oil wax to wooden products, improving their appearance and protecting them from environmental influences. This equipment is ideal for large-scale production and craftsmen seeking to achieve a high level of finishing for their products.

It is designed for rubbing oil wax into wooden blanks with a maximum thickness of up to 60 mm. It is used in board finishing lines, including after SSD-type aging machines.

Functionally, it consists of a base with a conveyor feed of the workpiece, 3 height-adjustable units with cylindrical brushes. The 1st and 2nd brushes are located at an angle of 200

The feed speed of the workpiece is regulated by a variator. The rotation speed of the working tool is also regulated by variators or frequency converters.

Characteristics

| Country of origin | Ukraine |

| State | New |

| Minimum belt speed | 2 m/min |

| Maximum tape speed | 12 m/min |

| Number of horizontal brushes | 3 pcs. |

| Maximum rotation speed | 950 rpm |

| Maximum brush diameter | 300 mm |

| Brush lift | Manual |

| Number of engines | 3 pcs. |

| Engine power | 1 kW |

| Dimensions of the material being processed | |

| Maximum material width | 400 mm |

| Maximum material thickness | 150 mm |

| Maximum length of material | 9000 mm |

| General parameters | |

| Weight | 350 kg |

| Length | 4000 mm |

| Width | 450 mm |

| Height | 750 mm |

| User characteristics | |

| Manufacturer | Z-machine |

Reviews

There are no reviews yet.