Scotch Bright system

₴1 530

Non-woven abrasive flap grinding wheels are used for decorative processing – matting, satin finishing, creating patina and other finishing treatment of surfaces made of bronze, brass, aluminum, stainless steel and other metallic and non-metallic materials.

Delivery methods

- We ship by any transport company or pick up yourself

Description

Scotch-Brite system (Scotch-Brite)

The Scotch-Brite system is a line of abrasive materials and tools developed by 3M. These materials are used for grinding, polishing, cleaning and finishing various surfaces. They are especially in demand in manufacturing processes that require high quality finishing or cleaning, as well as in areas where durability and cost-effectiveness of equipment are important.

Main features of the Scotch-Brite system:

- Wide Range of Products: The Scotch-Brite range includes a variety of abrasives including:

- Detergent: for removing dirt and residues of pollutants.

- Grinding discs: for grinding and leveling surfaces.

- Polishing and finishing materials: to achieve a high level of gloss and finish.

- Brushes and cloths: for cleaning surfaces from dirt, rust and oxides.

- High performance: Scotch-Brite abrasives are highly productive, providing rapid removal of dirt and defects with minimal operator effort.

- Minimizing damage: Because Scotch-Brite abrasives have a soft structure, they minimize the risk of damaging the surface being treated. This makes them ideal for working with delicate or thin materials such as aluminum, stainless steel or plastic.

- Durability: Scotch-Brite products are highly wear-resistant and durable. They retain their effectiveness for a long time, which reduces the cost of frequent replacement of abrasive materials.

Advantages of the Scotch-Brite system:

- Versatility: materials can be used for different operations on different surfaces.

- High efficiency: ensures fast and high-quality results with minimal effort.

- Safety: Due to its soft structure and low risk of surface damage, Scotch-Brite abrasives are safe to use.

- Cost reduction: Durability of materials and high efficiency help reduce equipment operating costs.

- Ease of use: The materials are easily integrated into enterprise processes due to their versatility and ease of use.

Application of the Scotch-Brite system:

- Mechanical Engineering: The system is used for cleaning, grinding and polishing metal parts such as engines, housings, automotive components and other products.

- Automotive Industry: Scotch-Brite is often used for finishing and polishing body parts, removing contaminants from surfaces and preparing surfaces for painting.

- Metalworking: In metalworking processes, such as removing oxide films or rust, Scotch-Brite materials are indispensable for achieving the desired surface quality.

- Furniture manufacturing and woodworking: The system is used for finishing wooden surfaces, leveling and polishing, as well as for creating texture on wood.

- Electronics industry: Used for gentle cleaning and polishing of plastic and metal components, as well as for preparing surfaces for coating.

- Construction: In the construction industry, Scotch-Brite is used for processing metal and plastic structures, as well as for cleaning and preparing building materials.

Base: non-woven abrasive material manufactured by Klingspor.

Abrasive material: electrocorundum

(AO), silicon carbide (SIC).

Features of use:

Grain size: P80 – P600 according to FEPA.

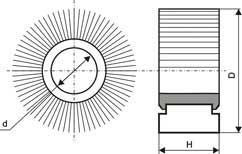

Sizes of manufactured flap wheels made of non-woven abrasive material:

from 100x30x32mm to 200x230x76mm (DxHxd)

D – outer diameter, mm

H – height, mm

d – diameter of the mounting hole, mm

D – outer diameter, mm

H – height, mm

d – diameter of the mounting hole, mm

Reviews

There are no reviews yet.