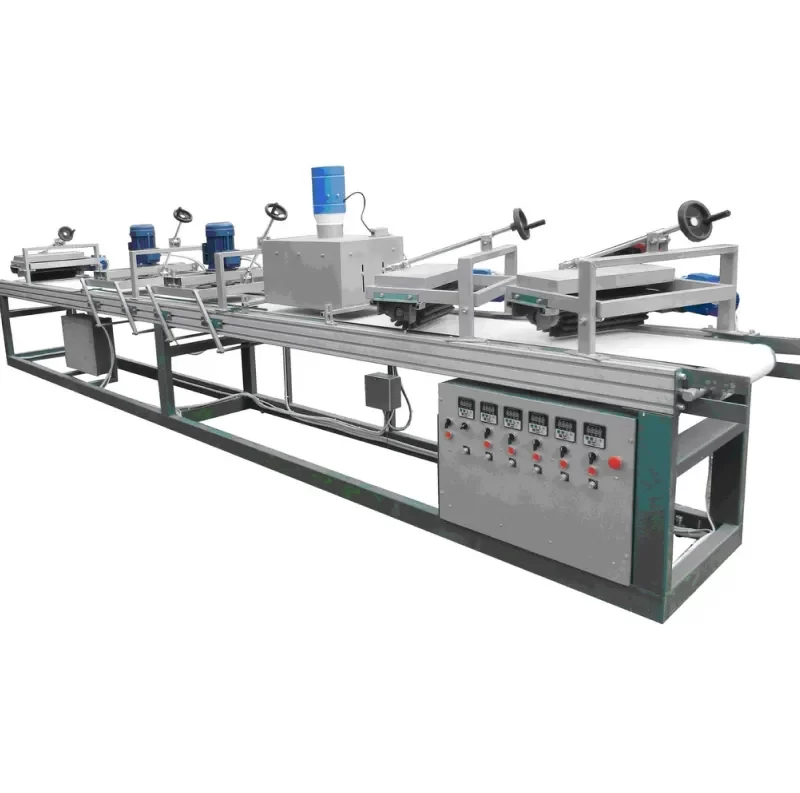

Wood profile sanding system

₴1 520

Sanding brushes are used for sanding profile surfaces of furniture fronts, lining, baseboards and various panels with sanded edges. Sanding brushes can be used for surface treatment to remove unevenness, unevenness of fibers and traces after cleaning.

Delivery methods

- We ship by any transport company or pick up yourself

Description

Wood profile sanding system

Profile sanding of wood is a process of processing wood products in order to achieve the required shape, smoothness and accuracy of contours on blanks with various profiles. It is used to create decorative elements, furniture fronts, panels and other products with a figured surface that require high precision. The profile grinding system includes a set of specialized machines and equipment that allow for precise grinding of complex shapes and contours of wood.

Advantages of the profile grinding system:

- Accuracy and detail:

Profile grinding allows achieving high precision in the processing of complex geometric shapes and contours, which is impossible to achieve with conventional grinding. - High quality processing:

Surfaces after profile grinding become perfectly smooth, without defects and burrs, which is important for decorative and finishing works. - Versatility of application:

Suitable for various types of wood and products with a figured surface: doors, window frames, tabletops, panels, furniture elements. - Flexibility and customization:

Modern profile grinding systems allow you to adjust the processing parameters (speed, pressure, angle) depending on the material and the desired result.

The main elements of the profile grinding system:

- Profile grinding machines:

These machines are equipped with special profiling elements that can be installed to grind specific shapes and contours. The machines can work with both straight and curved profiles. - Sanding discs and belts:

For profile grinding, special grinding discs or belts are used, which have different shapes depending on the required profile. They can be round, elliptical or shaped. - Cutting and grinding heads:

Some systems use specialized grinding heads that automatically adjust to the shape of the workpiece, providing precise and uniform grinding across the entire profile. - Dust removal system:

Since the grinding process produces a lot of dust, profile grinding systems are usually equipped with effective dust extraction systems that ensure a clean work area and operator safety.

Profile grinding process:

- Preparation of material:

The workpieces to be ground are prepared to size and shape for mounting on the machine. - Selecting a profile and settings:

Depending on the type of processing, the appropriate profile of the grinding belts or discs is selected. Parameters such as material feed rate, inclination angle and pressure are adjusted on the machine. - Grinding:

The workpiece is fed into the machine’s working area, where the grinding element processes it according to a given profile. During the work, the parameters can be adjusted to achieve the best result. - Final processing:

After profile grinding, the surface can be further processed to improve quality (e.g. using polishing discs).

Application of the profile grinding system:

- Furniture production:

Grinding of complex parts such as facades, panels, decorative elements. - Woodworking for construction:

Sanding of window frames, door frames, decorative wooden elements. - Production of art products:

The process of grinding shaped and carved wooden products that require high-precision processing. - Painting and varnishing:

Preparing wood surfaces for coating to ensure a smooth and even surface.

Main types of profile machines:

- Profile milling machines:

Used for cutting and grinding complex profiles on wood surfaces with high precision. - Profile grinding machines with belt:

They can be used for grinding straight and curved profiles. The grinding belts are stretched on special rollers that follow the specified contour. - Profile grinding disc machines:

Discs with different abrasive coatings are used for grinding materials with different types of profiles.

Conclusion:

The profile wood sanding system ensures precision and high quality processing of complex shapes and contours, which makes it indispensable in the woodworking and furniture industries. This technology allows you to create products with flawless surfaces, which is important for decorative and functional elements.

Sanding brushes are used for sanding profile surfaces of furniture facades, lining, baseboards and various panels with sanded edges. Sanding brushes can be used to process surfaces in order to remove irregularities, uneven fibers and traces after stripping.

The highest performance of this system is achieved during intermediate sanding of workpieces between the first and subsequent varnish coatings.

2. MULTI-FLEX System

The tool is a set sector brush that allows grinding profile surfaces of workpieces and can be installed on various machines and devices with a spindle speed of 800-1000 rpm.

3. F65

Excellent properties for intermediate grinding and profile processing

4. F80

The best solution for fine and fine grinding of a deep profile

Grinding can be performed both on machines with manual feed of the workpiece and on pass-through equipment. At the same time, due to the elasticity of the brush elements, the formation of unpolished zones on the processed profile surface is excluded.

A design feature of this system is the ease of replacement of the brush elements. The brush element is made of natural fiber – agave, which has antistatic properties.

PRO-FLEX System

Lightweight sanding brushes are the ideal tool for manual sanding.

Standardly supplied elements P2 and B2 are easily mounted on P-50 machines supplied by our company

MULTI-FLEX solid drum for 24 brushes h=50 mm

Reviews

There are no reviews yet.